Original “R2R” Processing Technology

- TOP

- Products and service

- Processing and services

- Original “R2R” Processing Technology

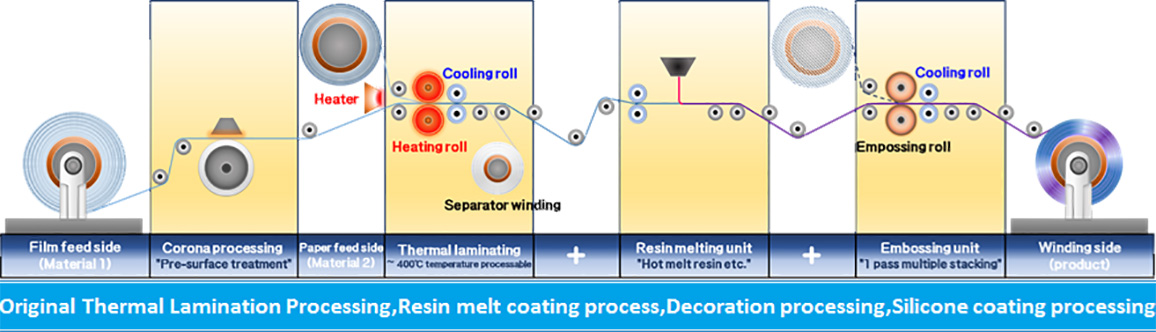

Original "R2R" Processing Technology

Based on experiences and knowledge, we can respond to various customers needs with original “Roll to Roll” Processing technology combining new processing technology and current technology.

We can process the film material into the shape and size of the customer's request.

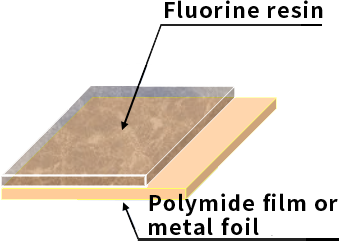

Original Thermal Lamination Processing

We can carry out laminate processing such as metal and resin, resin and resin which could not be done with conventional lamination technology.

| Feature |

|

| Application example |

|

| Composition example |  |

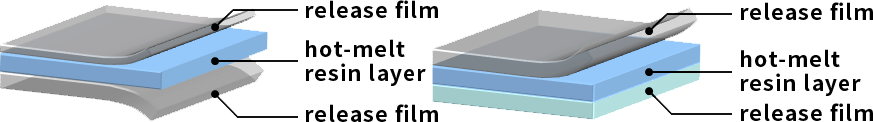

Resin melt coating process

Resin melt coating process heats hot melt material and film formation.

Laminated products, Single layer products, Compound products, etc. are available.

| Feature |

|

| Composition example |  |

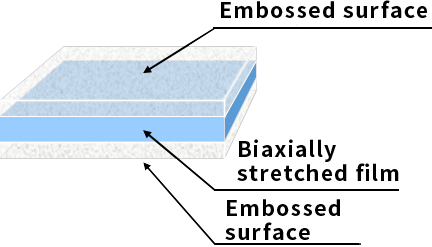

Decoration processing (emboss processing)

Embossing on the film surface

(single side and double side simultaneous processing possible)

| Feature |

|

| Application example |

|

| Composition example |  |

Silicone coating processing

| Feature |

|

| Application example | Composite sheet (silicone + other plastic film film etc.)※Please inquire details about the specification. |