PANA-PEEL Release・Transfer film

- TOP

- Products and service

- Features of Products

- FUNCTIONAL FILM

- PANA-PEEL Release・Transfer film

PANA-PEEL

Non silicone type

low silicone type

-

Release・Transfer film

NP・TP・SG・SM

NP series

PANA-PEEL NP series is a release polyester film coated to silicone release treatment.

Features FEATURES

-

It enables stable release properties.

-

We can chose from various thickness of base film.

Main applications PANAC is here!

-

For a backing sheet for punching pressure sensitive adhesive sheet

-

For a protective film of adhesive exposed parts of punching processing products

-

For a release film of adhesive film

Characteristic CHARACTERISTIC

| Application Type | Type | Peeling force[N/25mm]*1 | Residual adhesion rate[%]*2 |

|---|---|---|---|

| General purpose type | NP-75-SA | 0.028 | 87 |

| NP-75-A | 0.031 | 93 | |

| NP-75-B | 0.050 | 93 | |

| NP-75-C | 0.126 | 91 | |

| Atmospheric exposure control type | NP-75-Z-01 | 0.027 | 97 |

*1 Release strength measurement method: Standard tape-31B manufactured by Nitto Denko corporation.Measurement condition: Peeling speed 300mm/min, Peeling angle 180°

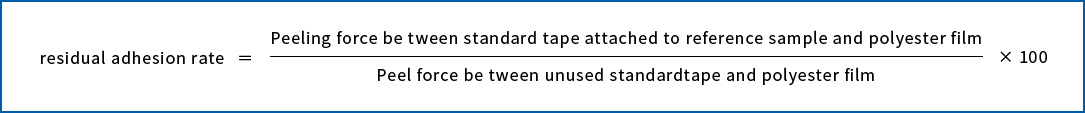

*2 Method of measuring residual adhesion

-

After Adhering the unused standard tape to the olefin film and refernce sample and then both samples will be heated in the same way as the peel force measurement.

-

After peeling off from both the olefin and the reference sample, then adhered to the polyester film.

-

After leaving these samples at room temperature for 30 minutes, measurement was carried out and the residual adhesion rate was calculated by the following formula.

※The indicated values are measurement values, not guaranteed values.

TP・SG・SM series

Pana Peel TD and SG series are films which are coated with release treatment on polyester film.It is compatible with various separability and wettability properties and is excellent in smoothness, so it can be used as a casting mount sheet for acrylic resin or silicone elastomer sheet.

Features FEATURES

-

It is excellent in heat resistance and solvent resistance and shows stable peeling transferability.

-

It has various range of different peeling properties from light separation to heavy peeling.

Main applications PANAC is here!

-

For various resin film forming ・ transferring mount sheet.

-

For various ink transfer backing sheet.

-

For a backing sheet for punching process.

-

It is suitable for backing sheets of silicone elastomer sheets used for heat radiation sheets.

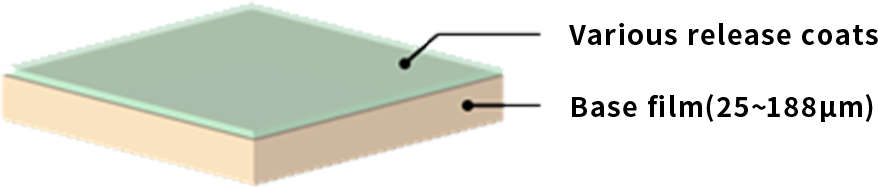

Composition COMPOSITION

Characteristic CHARACTERISTIC

| Type | Release properties | Coating layer type | Features | Release strength(N/25mm)* | Contact angle (deg) | Surface wettability (μN/cm) |

|

| RT×24h | 130℃×1h | ||||||

| TP-01 | Moderate | alkyd | Less migration | 2.2 | 7.0 | 94 | <300 |

| TP-03 | Light | alkyd | High heat resistance. High residual adhesion rate | 0.3 | 3.2 | 108 | <300 |

| SG-1 | Heavy | melamine | Stable properties for ink and resin,less migration | 9.0 | 15.3 | 75 | 370 |

| SG-2 | Heavy | melamine | Improved releasing property for silicone elastomers | 4.0 | 8.8 | 105 | 320 |

| SM-1 | Heavy | melamine | Matte shape formed type | 8.0 | 12.5 | 83 | 400 |

* Release strength measurement method: Standard tape-31B manufactured by Nitto Denko corporation.Measurement condition: Peeling speed 300mm/min, Peeling angle 180°

※The indicated values are measurement values, not guaranteed values.